From reactive to reliable – see inside your machines with Optimize Edge

Keeping machines running is critical for productivity and profitability. Yet many companies still rely on fixed service intervals or emergency repairs when something breaks down. Both approaches are costly, inefficient, and put unnecessary strain on people and equipment.

Optimize Edge changes this.

By combining advanced condition monitoring with smart analytics, it gives you a real-time window into your machines. The system continuously measures vibration, temperature, acoustic signals, and magnetic fields, turning complex data into simple health insights. This enables you to spot problems early, predict failures before they happen, and schedule maintenance exactly when it is needed.

The result is fewer breakdowns, lower maintenance costs, and longer equipment lifetime. In fact, predictive strategies powered by Optimize Edge can reduce unplanned downtime by 30–50% and cut maintenance expenses by 10–40%. Every avoided stop translates into more stable production, higher OEE, and significant savings.

Advanced Monitoring Made Easy

Key Benefits

Optimize Edge combines vibration, temperature, acoustic, and magnetic field data in one intelligent sensor. It translates advanced measurements into simple health insights, empowering your team to make data-driven decisions.

Who owns the data collected by Optimize Edge?

You do. Your data always belongs to you, and it is securely stored in the cloud.

Can I access my data anytime?

Yes. You can download it anytime or connect via a secure API.

Can Optimize Edge reduce false alarms?

Yes. Multi-sensor data is cross-validated to deliver reliable insights.

Is Optimize Edge wireless?

Yes. It uses secure wireless connectivity for simple, cable-free installation.

How long does the battery last?

Up to five years, and it’s easily replaceable.

Simple to deploy, built to last.

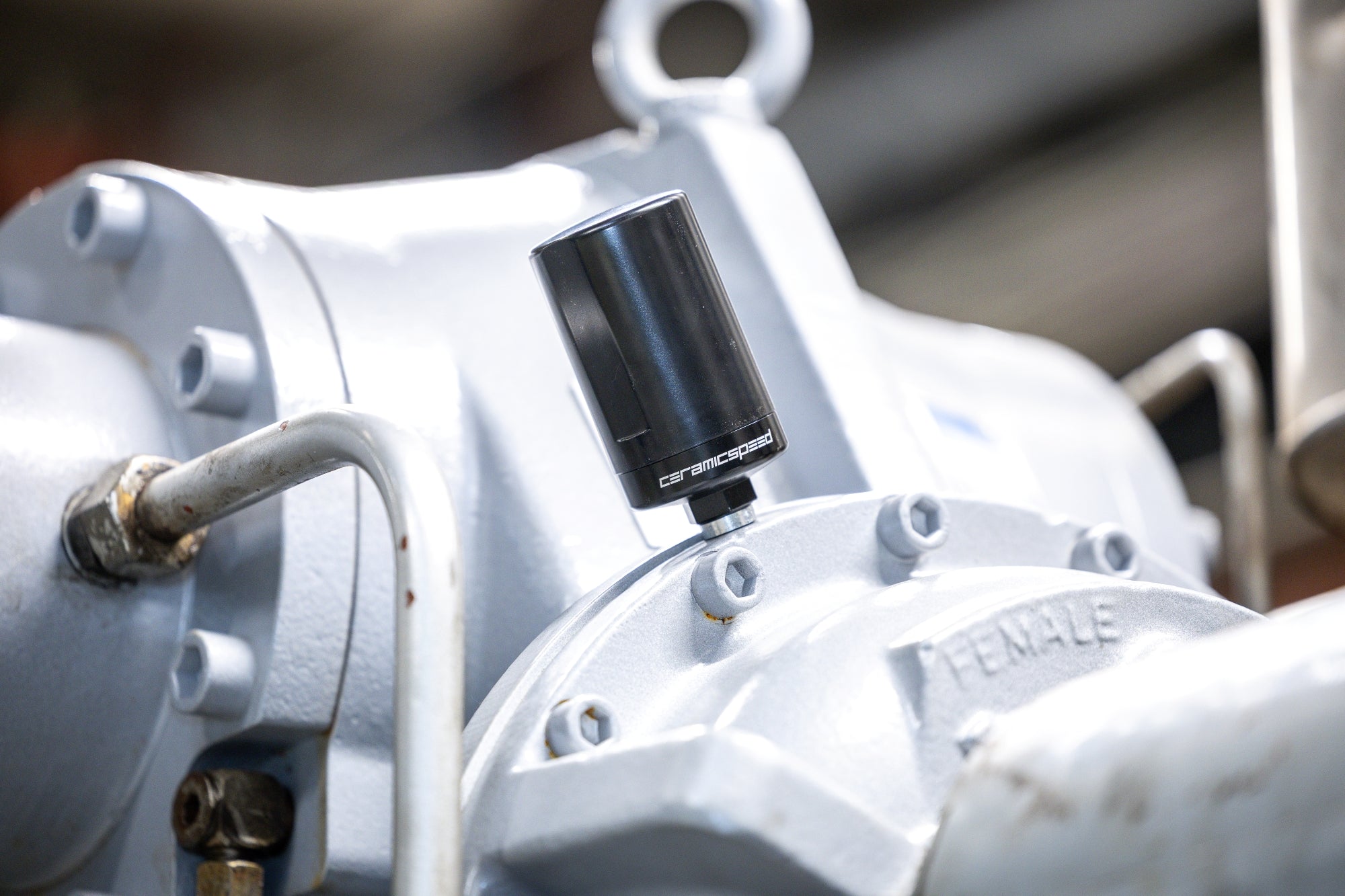

Unlike traditional monitoring systems that require costly cabling, Optimize

Edge is fully wireless and battery-powered. It installs quickly with a simple

M6 mount and runs for up to five years on a single industrial-grade battery.

With dual BLE and LoRaWAN connectivity, data flows reliably even in challenging

environments with steel and concrete.

Actionable insights, not noise.

Optimize Edge uses multi-sensor intelligence and an advanced health algorithm with more than 100 machine parameters. That means fewer false alarms and thresholds tailored to each individual asset. Through the Optimize Dashboard, you get clear health scores, trend views, FFT/HFFT analysis, and instant alerts - everything you need to make informed decisions in time.

Your data, your control.

All data belongs to you. It is securely stored in the cloud and can be accessed

anytime via the Dashboard or integrated into your own systems through API.

Transparency and ownership are part of our promise: your insights, your

decisions.

Scalable across industries.

From manufacturing, cement, and mining to energy, utilities, food &

beverage, HVAC, and transport—Optimize Edge scales effortlessly across sites and industries. Whether you monitor one production line or multiple facilities worldwide, the system grows with your needs.

In short: OptimizeEdge helps you move from reactive firefighting to proactive reliability. It gives you peace of mind, reduces risk, and frees your team to focus on what matters most—keeping production efficient, safe, and sustainable.